Quality Control

Guaranteeing our Standards for Construction

QC Focus Goals:

- Finding Solutions before the Problems

- Producing Watertight Construction

- Ensuring Zero Punchlist Projects

- Provide Total Customer Satisfaction

Pre-Construction Planning

The essential details describing waterproofing measures, facade details, brick control joints and other details aren’t always fully described in a project’s plans. We take several measures to ensure the final project meets the Client’s expectations of quality workmanship before construction starts

- Pre-Construction review of project designs and documents

- Pre-Construction conferences to communicate details with Foremen and Designers

- On-site mockups to verify material compatibility and transition quality

Watertight Installations

Since Block Flashings, Drainage Channels, Transition Sealing and Lapping Details often aren’t called for by the Designers. We take measures to guarantee their inclusion in the final project during our plan reviews, as they are essential components to leak-proof masonry.

Doing it Right the First Time

We extend our QC process throughout our projects. In addition to our extensive pre-construction planning, we encourage our Workmen and Foremen to take a step back and assess their work regularly. When requested, we also make use of inspections by 3rd party engineering firms to establish that our project meets the client’s expectations and help us meet our goal of providing Zero-Punchlist and low maintenance installations.

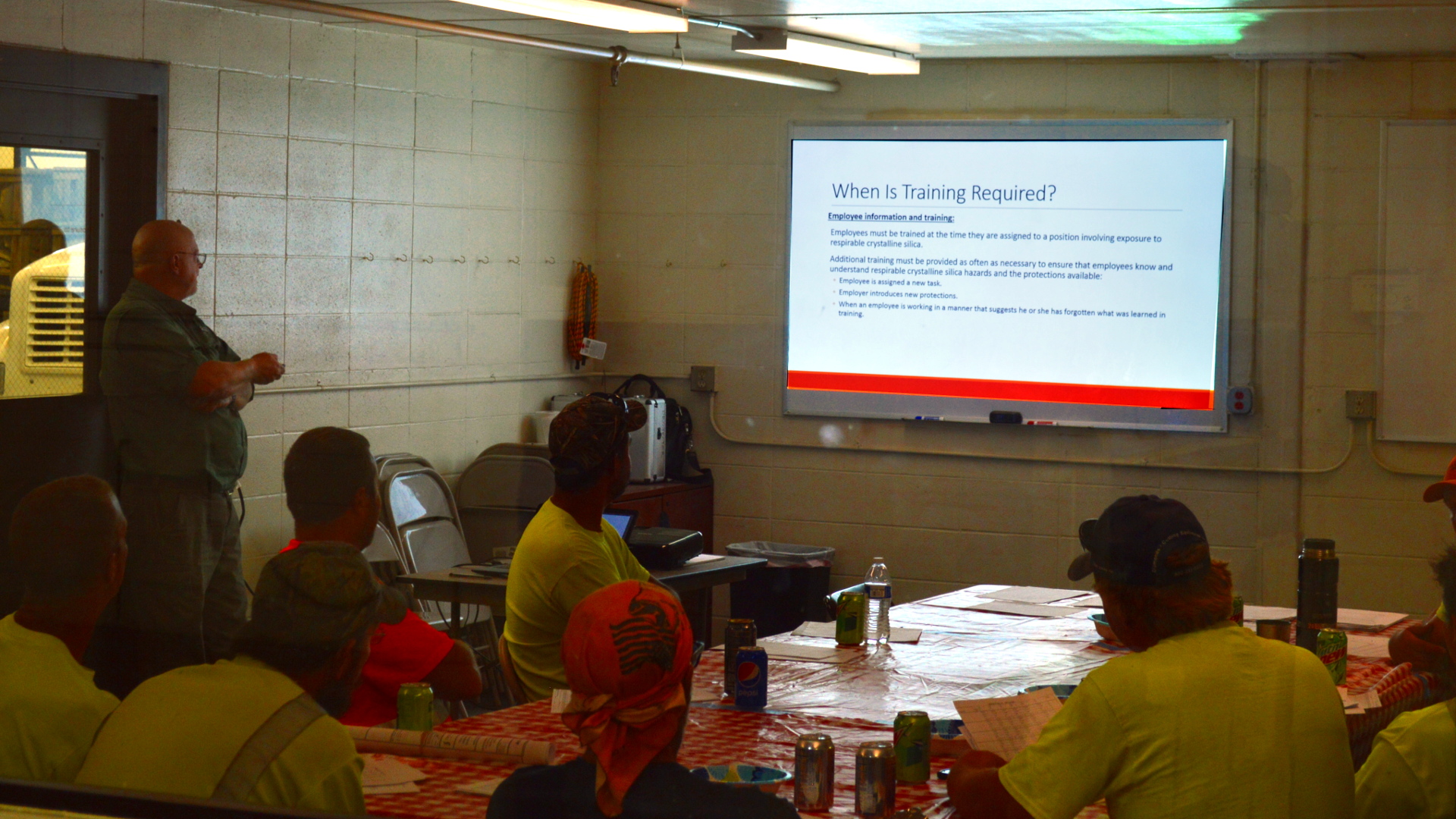

QC Optimization

We hold QC workshops where our Foremen review our projects to audit our QC policy and its implementation. This practice is to ensure that our Workers’ knowledge of our QC policy and the process itself is always improving.